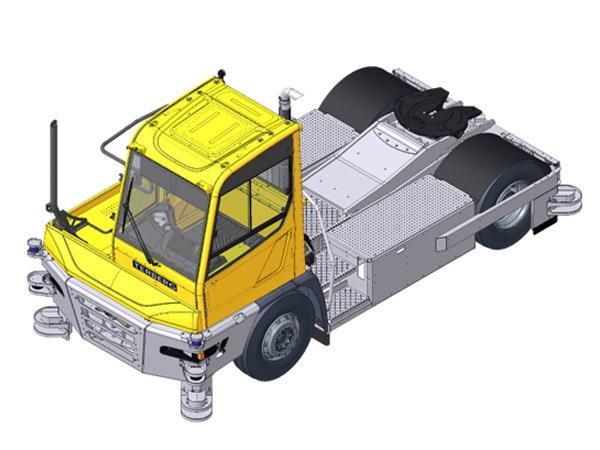

Terberg RT303EV

As many of you are aware, we have been working hard to develop the first Terberg RT tractor as a fully electric version.

The first unit was build in the first half of this year and it is almost ready for its first tests in a real life port environment. This tractor will be used as a proof of concept, to test and see how this design can be used in the demanding RoRo operations at our customers.

The term “proof of concept” clearly indicates this product is far from ready for series production. As building a good and reliable Yard tractor in an EV version was not easy, you will understand the challenges our engineers have faced to develop an EV RoRo 4x4. There is not much space for the batteries and other components as the tractor has to be manoeuvrable, low, with a long range and still have a spacious cabin for the driver. We think we have already come a long way and will proudly present this new product range to you during the upcoming Distributor Days.

BCxx3EV

Terberg noticed that the swap body concept is growing in popularity. Our answers to this are the new BCxx3 and BC203EV. Compared with a road truck the Swap Body Carrier is more focused on shunting the swap bodies, with its heavy duty design and hydraulic lift table.

The negative effects of diesel emissions and the growing demand for electric vehicles were the key factors to develop an electric Swap Body Carrier. The BC203EV is cleaner, quieter, has fewer moving parts and has less chassis vibration.

The YT203EV was introduced in 2020. This electric yard tractor was equipped with a completely new drivetrain. The drivetrain was developed based on the experience and knowledge that we gained over the years. The BC203EV is equipped with the proven driveline technology of the YT203EV and all the swap body features of the new BCxx3.

During the distributor days 2023 you can check out the new BC203EV.

Drive by Wire Diesel

The past years we have been working hard on the Drive by Wire (DBW) functionality of the YTxx3 machines.

This DBW platform can receive commands from the automation kit or tele-operation kit with a remote driver in an office. These commands are converted to actions in the same way the driver would do this in a manual machine. Now the first CE-marked YT193 DBW pre-series diesel machine has been produced, and the YT203EV DBW will follow next year.

How did we develop this machine, where are we today and which challenges have we overcome so far and expect to see in future? What is the role of the autonomous kit suppliers, the impact on the DBW machine and business models? What are the requests and expectations of our customers? Altogether an interesting mix about future technology we would like to share with you during our distributor days.