The past years we have been working hard on the Drive by Wire (DBW) functionality of the YTxx3 machines.

This DBW platform can receive commands from the automation kit or tele-operation kit with a remote driver in an office. These commands are converted to actions in the same way the driver would do this in a manual machine. Now the first CE-marked YT193 DBW pre-series diesel machine has been produced, and the YT203EV DBW will follow next year.

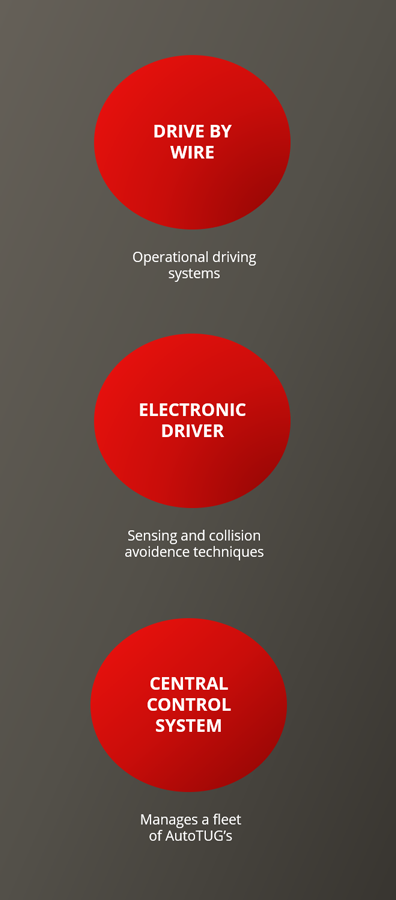

Terberg developed its automation architecture based on three function layers.

DRIVE BY WIRE

The Terberg "drive by wire" vehicle can be controlled via a CAN-bus interface that can be used for further automation or development. In the vehicle, an automation layer is integrated with relevant safety levels in accordance with ISO 13849-1/2. The "drive by wire" controls the operational systems of the vehicle, such as the drivetrain, braking system, steering system, coupling plate, lift table, and lighting.

ELECTRONIC DRIVER

The second layer is the “Electronic driver” that uses the drive by wire layer and is able to “drive” the vehicle, meaning that the vehicle is able to maneuver, in a controlled manner along a preprogrammed path. This functional layer, developed by autonomous partners, gives the flexibility to connect the vehicle in a customer automation program cable of controlling vehicles.

TERMINAL OPERATING SYSTEM (TOS)

The 3rd layer is the system from which the AutoTUG™ gets its instructions, the central logistics system that manages a fleet of AutoTUGs.

Kramer Group, a major Rotterdam depot and container terminal operator, StreetDrone, a leading provider of autonomous yard truck technology, and Terberg, Europe’s largest manufacturer of yard trucks...

Terberg and Fernride announced their collaboration to develop an automated terminal tractor CE certified for commercial production. This solution offers both teleoperated and autonomous driving...

Terberg and Aidrivers have signed a memorandam of understanding (MOU) to work together on the deployment of an autonomous terminal tractor solution for port terminals that is safe, scalable and...

In addition to our drive by wire system, we are partnering with suppliers to integrate an autonomous system allowing AutoTUG to share traffic lanes with conventional trucks. This includes cameras, radars and laser-based sensors for navigation, collision avoidance and pedestrian detection.

A central computer on the vehicle processes all sensor information in real time, takes decisions, and verifies the route. By introducing more intelligence to the vehicle, it can resolve issues onboard, without the complexity of all decisions being made in the Equipment Control System.